Following the major release of the new version of Solvo.TOS for railway terminals, Maksim Maksimov, Commercial Director, TOS systems, at SOLVO, explained the role of new features help container terminals to more effectively solve their logistics goals to the representatives of Russian ports and railway companies during his speech at the conference "Perspective for the development of the Big Port of St. Petersburg".

“In the latest version of Solvo.TOS, which became available to our customers at the end of 2020, we developed a few interesting features such as the addressed allocation of railcar capability and the extended terminal rail-track accounting. In the "Rail-track network" module of the system, not only freight, but also non-freight tracks are now distinguished, where it is possible to lay wagons on the sludge and control shunting operations, supply and retrieval of trains, coupling and uncoupling. Also the system allows planning railcar allocation sequence wagon or fitting platform position on tracks. Distances to each carriage are automatically taken into account by the system during job assignment to СHE operators,”– says Maxim.

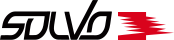

For example, if earlier only the sequence of cars on the track was taken into account, but there was no information about their territorial location, now the system records the location of each car literally up to a meter. At job scheduling or CHE dispatching, the system takes into account the exact geographical location of each railcar and distances between the objects are taken into account when planning loading/discharge operations and CHE movements.

“Thanks to the Solvo.TOS scheduling algorithms, you know exactly how long it takes for a crane or reach-stacker to get there,” – explains Maximov.

The module of the system has also been strengthened in terms of block train management. New allocation rules have been added: now, when containers are brought to the terminal for shipment by a block train or received from the sea, special Solvo.TOS rules group containers at the warehouse area so that they can then be conveniently loaded onto a block train.

Also, the rules for planning the loading of containers on fitting platforms, taking into account their "yellow" and "green" run, destination stations, and so on, were added to the Solvo.TOS system.

“Now users can write their own scripts for automated railcar planning configuration, container selection for loading, taking into account the local technical requirements depending on wagon type and model, passing direction, destination station, FIFO principles, and so on. This process includes a lot of verified mathematical calculations and algorithms in order to plan everything in an optimal way, – the expert describes. – In terms of document management, the container terminal does not need to switch from one system to another, all the related paperwork can be handled using a single Solvo.TOS platform”.

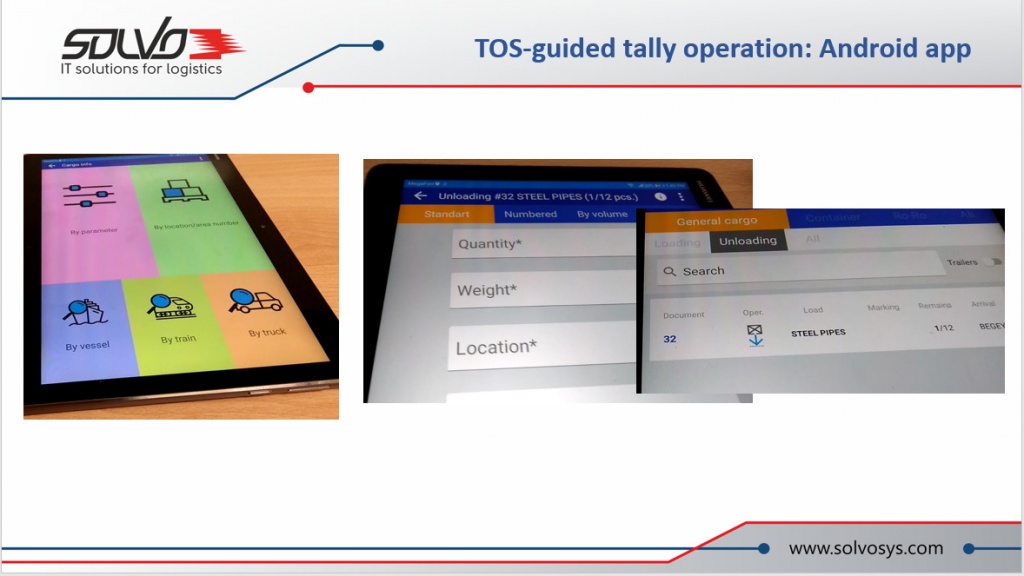

Many updates have also been made in terms of TOS UX/UI. Special user interfaces were developed for tallymen and equipment operators allowing the use of touchscreen Android tablets. E.g the tallymen can now swipe, photograph container defects, and seals. These interfaces can work not only with containers, but also, for example, when unloading and filling general cargo.

“We have improved and changed the client's web portal. It has become more user-friendly and ergonomic. Here terminal clients – cargo forwarders and line agents – can view information about their cargo, easily submit cargo handling operation requests in real time for weighing, filling, unloading, and so on, issue a power of attorney for the truck-driver, sign it with an electronic signature. Here it is possible to handle all related paperwork for all interested parties including Customs authorities", - specifies Maximov.

Convenient web interfaces of the system allow you to control the terminal from home or any other place with the Internet connection. Interfaces for mobile devices are available to monitor the status of ongoing work. With their help, you can see how much and what kind of cargo was accepted, get statistics and analytics for various metrics.

“We have also improved the Solvo.KPI module with a flexible user access management functionality and smart filters to obtain information about the terminal's performance across a wide range of indicators. One can monitor the productivity of the terminal in real time through a set of user-customizable smart-looking graphs, tables and diagrams forming a user KPI dashboard, – concludes Maxim Maximov. – We constantly receive feedback from our customers, collect information about their needs and what their expectations are from our product, and we work in this direction".