Requirements for speed and quality of services in logistics have been steadily increasing over the past few years. Ports and terminals are no exception. Participants in the global supply chain increasingly need to quickly exchange data with each other. This is another growing trend. Therefore, the world's leading developers of Terminal Operating Systems, such as SOLVO, today help companies not only automate internal operations, but also integrate in a single digital space with other organizations. In fact, TOS solutions help to form a digital ecosystem based on a port or cargo terminal, which integrates all other systems and equipment, and also interacts with the e-flow systems of other companies and government regulatory organizations.

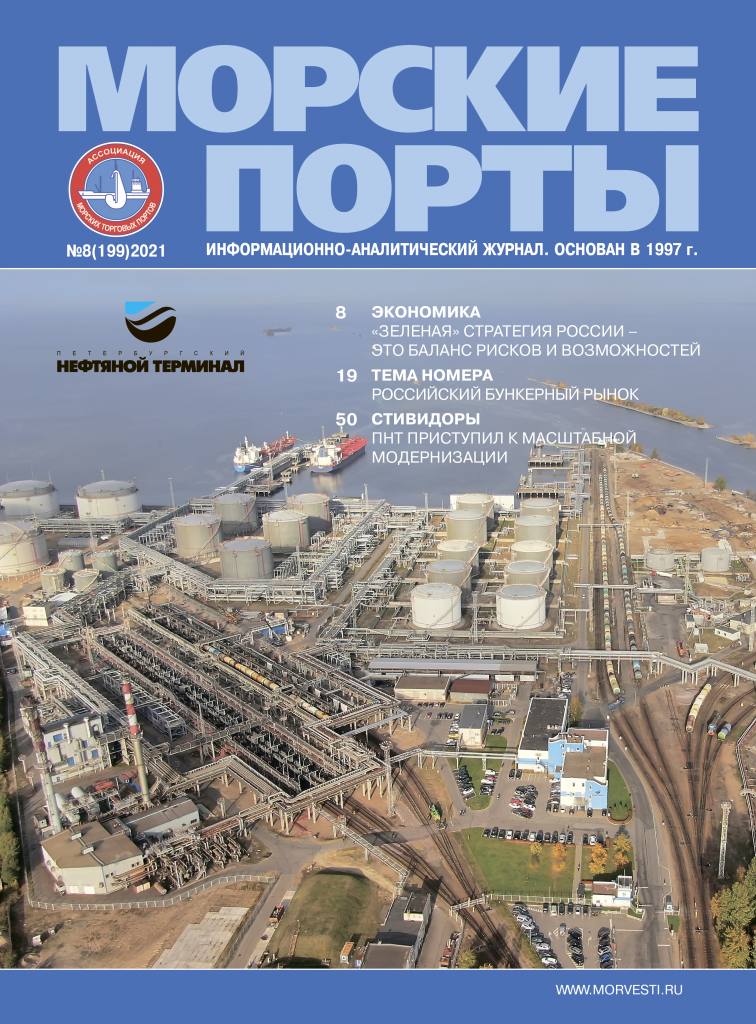

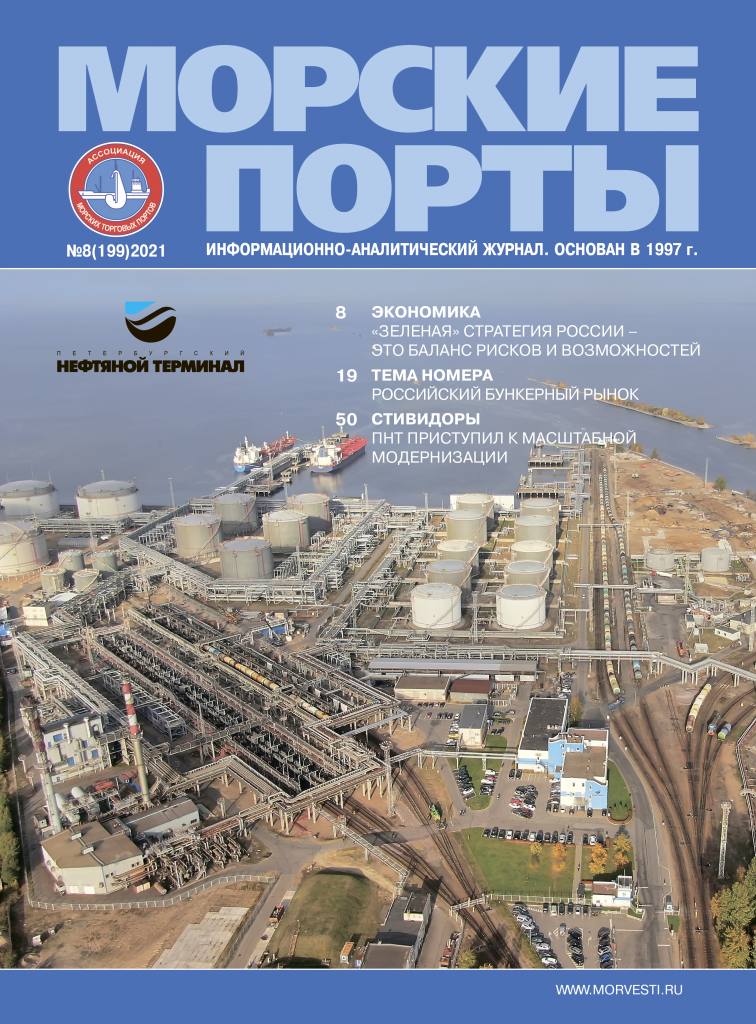

More details on how it works can be found in the Russian magazine "Sea Ports". We have translated this article for our readers. Follow the link to read the

original article in Russian.

Perfect order in every process

TOS implementation first of all means the automation of all internal processes. It is possible to reduce the number of errors in logistics operations due to the human factor by more than 90% if the system integrator is deeply immersed in the project and the specifics of each customer, and if he developed a competent and systematic approach to automation.

Let's take a look at such a complex direction as general cargo. For example, it is quite simple to systemize containers with standard dimensions and weight characteristics, and even more complex Ro-Ro cargo, as a rule, still have certain linear dimensions and weight. General cargoes are radically different in size, weight, types and number of packages. It can be complex factory machinery in 10 boxes, roundwood, scrap metal, various cargoes in barrels and reels, paper rolls, plywood, piece cargo and much more.

If the terminal is not automated, general cargo in the storage area is placed at the discretion of the responsible employee. But even the most responsible specialist will find it difficult and time-consuming to optimally plan the placement of general cargo in the storage area using strategy and forecasting. Smart computing algorithms of Solvo.TOS think about everything at once: how to use every free square meter of the storage area more efficiently, how to combine all cargoes with each other, which of these cargoes will be shipped from the terminal earlier, and which later, what equipment will be shipped from warehouse area and where they will go next. Each stage of the complex technological chain of handling general cargo is under control.

The automation system takes and processes data from bills of lading or consignment notes, as well as information about the cargo nomenclature sent to the terminal. Further, the system creates separate storage rules for each such nomenclature, generates working technological maps that regulate what type of load handling machinery should be sent to shunting operations with one or another cargo.

Using the collected statistics, Solvo.TOS calculates how to:

- allocate space in the storage area as efficiently as possible, considering the compatibility of general cargo;

- save the time required to find a free cell for general cargo storage and to set tasks for load handling machinery and terminal employees;

- keep records of such goods so that nothing is lost, as well as effectively organize their shipment.

Solvo.TOS automatically generates handling rules and storage logic for any type of cargo: general; Ro-Ro; bulk and break bulk (fertilizers, grain, pellets, coal etc.); goods packed in bags and boxes (cacao, sugar, rice); construction materials; sawn material and round timber; metals (ferrous and non-ferrous); food, including perishable food (meat products, fruits); paper (in rolls and on pallets) and pulp; metal waste, machines and, of course, containers.

Solvo.TOS algorithms also take into account all the nuances when building a strategy for handling and placing сargo: from the geographical location of the terminal and its technical capabilities to plan for the acceptance and dispatch of all goods. It helps to optimally place all goods in the storage area and avoid a large number of stowages.

Vessel call planning helps to avoid confusion with transit cargo. Solvo.TOS receives an input document on the cargo from the vessel when it is still at sea, draws up a plan for cargo handling operations, considering what cargo will go on this vessel, which ones need to be moved to the railway or road front for further transportation, and which ones - to the storage area for short-term or long-term storage.

The railway module of Solvo.TOS organizes cargo handling operations with container and other types of freight trains.

The system saves the history of actions with each cargo, and this data can be available not only to the dispatcher, but also to the client of the terminal using a special web portal.

Digital ecosystem inside a terminal

Solvo.TOS forms a whole ecosystem inside a terminal.

On the one hand, the system controls and organizes all important business processes, on the other hand, it integrates with various equipment and software (ERP, electronic document management systems, OCR, security systems, additional equipment for cargo or transport identification, data collection and many other technologies). Solvo.TOS collects data from these systems, generates reports on their basis, builds the most optimal terminal management strategy.

Figuratively speaking, the system plays the role of the brain, that controls all the vital components of the terminal operation.

Each separate process is automated and, like a piece of a puzzle, connects with others into a common mechanism that forms tasks for employees and technics, plans cargo handling operations for vessels and trains, organizes visits of freight transport, and much more. The system helps to evenly distribute the resources of both people and equipment.

For example, a reachstacker can take a container from the second row in summer, but cannot do it in winter, because it is slippery - the system considers this seasonal factor and the capabilities of reachstackers when assigning tasks.

The time to complete tasks is also monitored. For example, a delay in unloading a vessel can result in loss of money. Solvo.TOS analyzes how long it will take to unload the vessel, and if it is clear that the time needed to complete the work is increasing, then it connects to help other equipment that performs less priority tasks.

And if the terminal has storage areas or the company has several logistics facilities, all of them can also be included in a single digital ecosystem.

Integration with global chain participants

Sometimes the terminal needs to integrate with systems of other companies for data exchange, client services and government services systems. All this is quite real with Solvo.TOS.

For example, the ports of Aktau and Baku in the Caspian region needed a single information space for the exchange of data on passengers and cargo. Each port has TOS of different vendors, one of them is Solvo. To solve the problem of communication between ports, the developers formed a single digital environment where these two operation management systems could exchange data.

The principle of communication between the two ports is similar to the usual communication in messengers for many people. But the dialogue takes place between the automation systems of the ports. Information is sent from system "A", transformed as needed, and then transferred to system "B". And vice versa.

As a result, users receive all the necessary information online in real time.

As we can see, modern IT technologies solve even the most non-trivial tasks today. The secret of success is the modularity and flexibility of TOS, as well as the experience and wide competencies of a system integrator.

Note that the SOLVO team has 26 years of experience in creating individual and complex IT solutions for warehouses, ports, railway and other types of cargo terminals.