In November 2017, SOLVO successfully completed the implementation of a 'Smart Container Terminal' at one of the rail container terminals of TransContainer in Novosibirsk, Russia.

The goal of the project, where SOLVO served as the general contractor and developer, was to deliver a comprehensive all-in-one real-time terminal management solution and a single information space for clients, stakeholders and contract partners of TransContainer.

Moreover, SOLVO’s experts designed and built a network infrastructure, installed server equipment along with mobile and video surveillance and OCR devices.

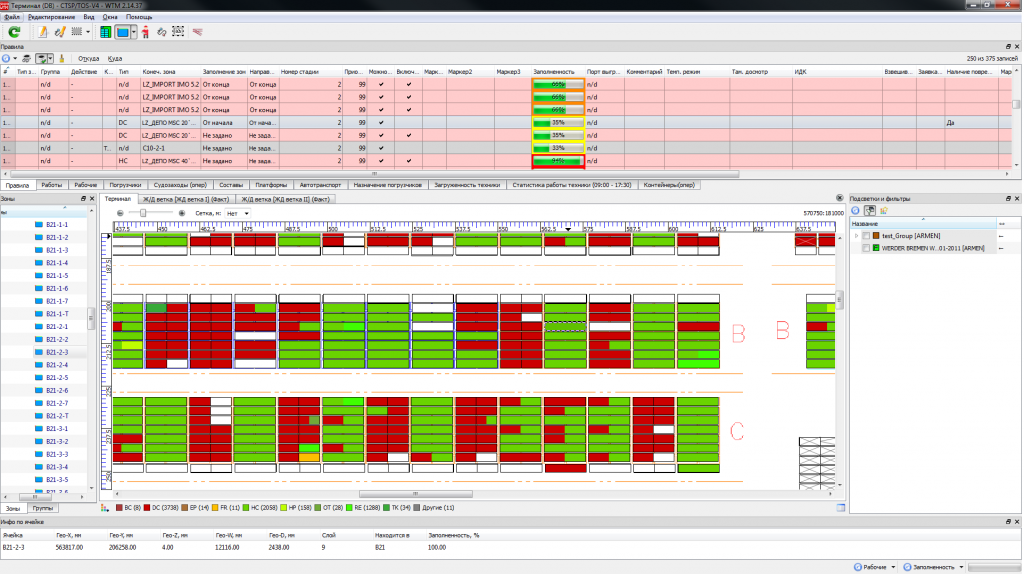

Smart Container Terminal (SCT) is a software-hardware package, developed based on Solvo.TOS for inland container terminals, video surveillance and OCR systems from SecureOS, provided by SOLVO partner company ISS, as well as the other 3rd party systems used at the terminal.

The final mix includes Solvo.TOS for planning and managing inland intermodal container terminal operations and document flow; optical character recognition (OCR) and registration system for incoming and outgoing cargo, trucks and rail-cars; Solvo’s gate management and optimization modules, existing tracking and accounting systems imposed by Russian Railways, Solvo.WEB portal for cargo-forwarders, cargo-owners and transport companies.

The main goal of the SCT is to manage automated cargo-handling operations in the yard based on monitoring of cargo flows, real time positioning data, state of containers and rail cars, client orders, and the dislocation of transport vehicles and CHE.

The functions performed by the SCT include:

Positioning of containers in real time;

Train loading with consideration of technical conditions and automatic loading check;

Support interaction with rail information systems;

Optimization of truck management via time-slotting, including automatic processing of client truck visit requests;

Automated gate control;

Automatic in/out-gate identification for trucks and trains via integration with SecurOS (OCR) – SecurOS Transit, vehicle numbers – SecurOS Auto and containers – SecurOS Cargo;

Automatic recording of acceptance-delivery agent actions during inspection;

Container train planning, including automatic creation of train schedules and rail car selection;

Optimization of loading/unloading plan creation;

Graphical real time representation of terminal layout, containers, equipment, personnel and processes with the help of the integrated terminal bird-eye viewer and editor Solvo.WTM®

Optimization of container distribution in the yard using preconfigured rules and strategies to minimize rehandles and unproductive moves;

Automated picking of unnumbered empty containers.

SOLVO carried out installation and mounting works in setting up the system infrastructure, enabling the automation of main processes at the container terminal, namely:

The implementation of the SCT system has already made it possible to:

Reduce truck processing time by 3 times;

Achieve at least 90% load capacity for container trains during shipping.

“The Smart Container Terminal is a new generation management system, which reduces possibility of human error, allowing to perform operations and accompanying document flow, to increase service quality and decision-making, as well as rationally optimize rail car and container resources to cut overall operating costs of the terminal,” reads the official TransContainer press release.

The productivity forecast, according to TransContainer, reads:

“The SCT will allow to reduce rail car idleness by 0.1 days, reduce rail car turnaround time by 0.1days, reduce container lay time by 2 days, reduce container turnover by 0.2 days, minimize unproductive runs during cargo-handling operations in the yard, which will, first of all, cut electricity and fuel costs, as well as maintenance and repair costs in the container yard.”

TransContainer concludes that “the implementation of this technology is very important for TransContainer since the new system will increase efficiency by, first and foremost, reducing dependency on human labor. Secondly, this system will raise work capacity alongside increasing cargo flows, improve decision-making and management processes, and raise quality of service, which will only strengthen the positive image of the company.”

TransContainer (MCX: TRCN) is an intermodal freight transport company based in Russia. It was founded as a subsidiary of RZD (Russian Railways)

It is Russia's main intermodal container transport and integrated logistics company; it transports over a million TEUs per year. The company owns about 60% of the total flatcar fleet in Russia, holds 52% of the rail container transportation market and 32% of the container terminal handling market in Russia. Transcontainer also owns about 60,000 ISO containers, owns a network of rail-side container terminals, which are located at 46 railway stations in Russia, and operates Dobra container terminal on the border of Slovakia and Ukraine. It also controls 50% of Kedentransservice, which offers terminal handling at 19 railway stations in Kazakhstan.